Kev Qhia Txog

SILIKE Si-TPV 2250 Series yog ib qho dynamic vulcanized thermoplastic silicone-based elastomer tsim los txhim kho EVA foaming cov ntaub ntawv. Si-TPV 2250 Series yog tsim los ntawm kev siv cov thev naus laus zis tshwj xeeb uas ua kom cov roj hmab silicone tau tawg sib npaug hauv EVA ua 1-3 micron particles. Qhov kev hloov kho tshwj xeeb no rau EVA foaming cov ntaub ntawv ua ke lub zog, toughness, thiab abrasion tsis kam ntawm thermoplastic elastomers nrog cov khoom zoo ntawm silicone, suav nrog softness, ib tug silky xav, UV tsis kam, thiab tshuaj lom neeg tsis kam. Nws tuaj yeem rov ua dua thiab rov siv dua hauv cov txheej txheem tsim khoom ib txwm muaj.

Si-TPV 2250 Series Eco-Friendly Soft Touch Material cov ntaub ntawv sib xws nrog ethylene-vinyl acetate (EVA) thiab ua haujlwm ua tus hloov kho silicone tshiab rau EVA Foaming, Kev daws teeb meem rau kev txhim kho EVA ua npuas ncauj cov ntaub ntawv hauv daim ntawv thov xws li khau hauv qab, cov khoom siv huv, cov khoom ua si nawv, cov lev hauv pem teb, cov lev yoga, thiab ntau ntxiv.

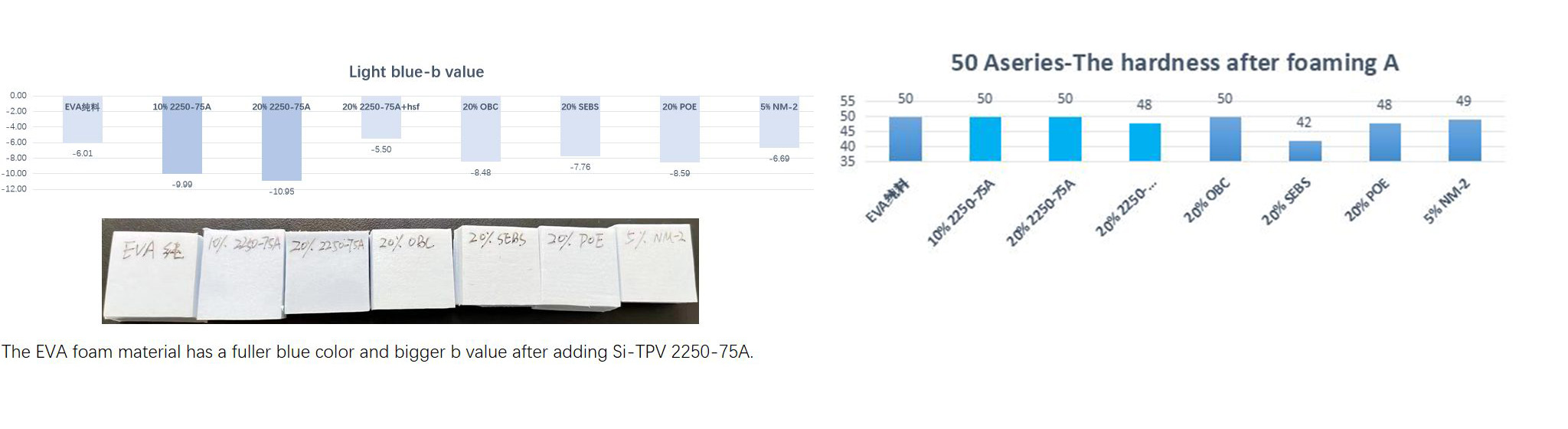

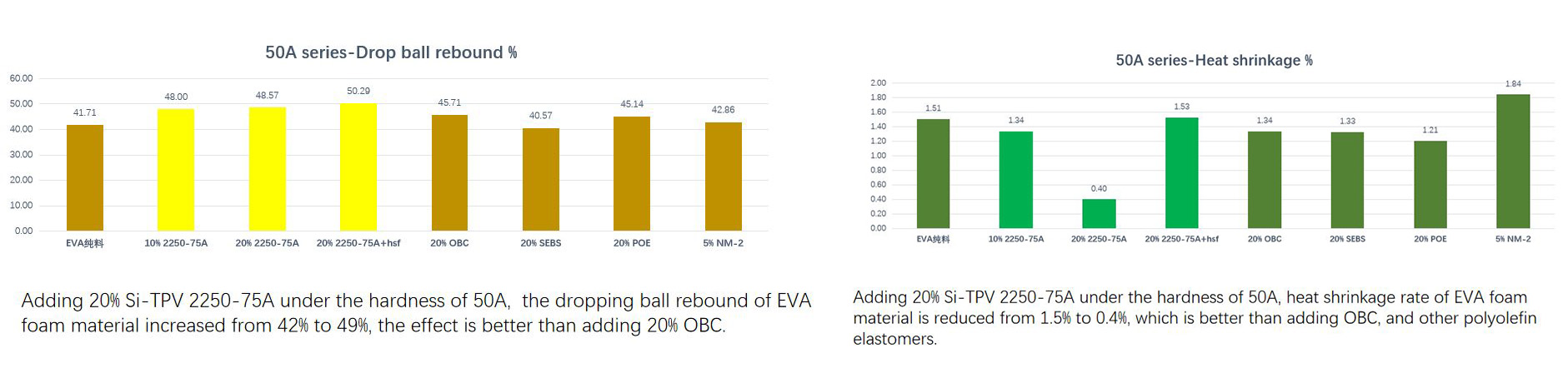

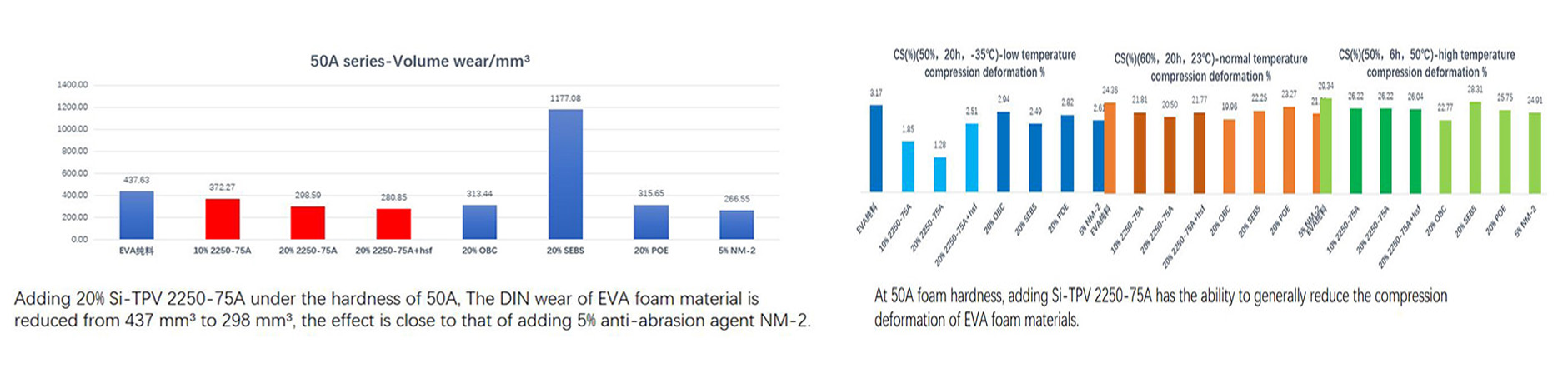

Piv nrog OBC thiab POE, Highlight txo qhov kev teeb tsa compression thiab cua sov shrinkage ntawm EVA ua npuas ncauj cov ntaub ntawv, txhim kho qhov elasticity thiab softness ntawm EVA ua npuas ncauj, txhim kho qhov anti-slip thiab anti-abrasion tsis kam, thiab DIN hnav raug txo los ntawm 580 mm3 mus rau 179 mm3 thiab txhim kho cov xim saturation ntawm EVA ua npuas ncauj cov ntaub ntawv.

Uas tau ua pov thawj tias muaj txiaj ntsig zoo Flexible Soft Eva Foam Material Solutions.

Cov Txiaj Ntsig Tseem Ceeb

Kev Ruaj Khov Kev Ruaj Khov

- Cov thev naus laus zis tsis muaj kuab tshuaj, tsis muaj plasticizer, tsis muaj roj softening, thiab tsis muaj ntxhiab.

- Kev tiv thaiv ib puag ncig thiab kev siv rov qab tau.

- Muaj nyob rau hauv cov qauv tsim uas ua raws li kev cai lij choj.

Si-TPV Modifier Rau EVA Foaming Case studies

Cov Si-TPV 2250 Series muaj qhov kov mos mos uas zoo rau daim tawv nqaij ntev, tiv taus cov av zoo, thiab tsis tas yuav ntxiv cov yas lossis cov tshuaj ua kom mos. Nws kuj tiv thaiv kom tsis txhob muaj nag tom qab siv ntev. Ua ib qho khoom siv Eva ua npuas ncauj uas sib xws thiab tshiab, nws yog qhov tshwj xeeb tshaj yog rau kev npaj cov khoom siv EVA ua npuas ncauj uas sib dua, ywj siab heev, thiab zoo rau ib puag ncig.

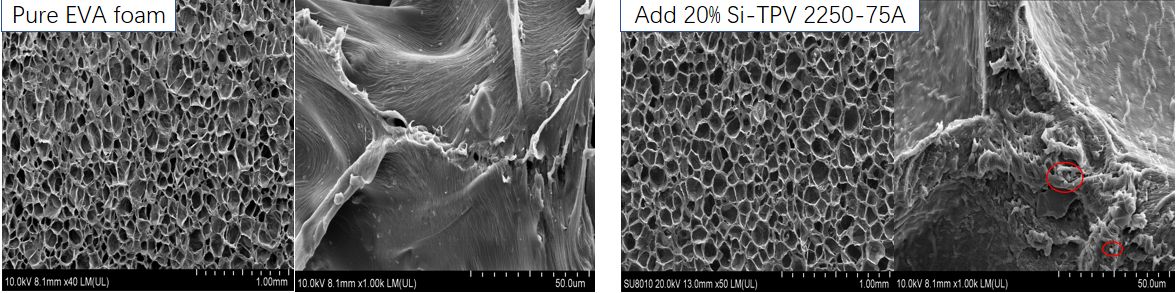

Tom qab ntxiv Si-TPV 2250-75A, qhov ceev ntawm lub cell npuas ntawm EVA ua npuas dej tau txo qis me ntsis, phab ntsa npuas tuab, thiab Si-TPV tau tawg hauv phab ntsa npuas, phab ntsa npuas ua ntxhib.

Kev sib piv ntawm Si-TPV2250-75A thiab polyolefin elastomer ntxiv cov teebmeem hauv EVA ua npuas ncauj

Daim Ntawv Thov

Tus hloov kho Si-TPV tshiab uas zoo rau ib puag ncig thiab muaj zog rau cov khoom siv EVA ua npuas ncauj uas tau hloov kho ntau yam kev lag luam hauv lub neej txhua hnub thiab kev ua lag luam. xws li khau, khoom siv huv, ncoo da dej, khoom siv kis las, lev hauv pem teb/yoga, khoom ua si, ntim khoom, khoom siv kho mob, khoom siv tiv thaiv, khoom siv tsis plam hauv dej, thiab cov vaj huam sib luag photovoltaic ...

Yog tias koj tsom mus rau cov kev daws teeb meem rau kev ua npuas dej supercritical, peb tsis paub tseeb tias nws puas yog rau koj, tab sis qhov Si-TPV modifier reshaping tshuaj foaming technology no. Rau EVA foaming manufacturers tuaj yeem yog lwm txoj hauv kev los tsim cov khoom sib dua thiab yoog tau nrog qhov ntev meej.

Cov Kev Daws Teeb Meem:

Txhim Kho EVA Foams: Kev daws teeb meem EVA Foam nrog Si-TPV Modifiers

1. Kev Taw Qhia Txog Cov Khoom Siv Ua Npuas Ncauj EVA

Cov khoom siv ua npuas ncauj EVA yog ib hom ua npuas ncauj kaw uas tsim los ntawm kev sib xyaw ntawm ethylene thiab vinyl acetate copolymers, nrog rau polyethylene thiab ntau yam tshuaj ua npuas ncauj thiab cov tshuaj catalysts uas tau tsim thaum lub sijhawm tsim khoom. Lub npe nrov rau nws cov cushioning zoo, kev nqus dej, thiab kev tiv thaiv dej, EVA ua npuas ncauj muaj cov qauv sib dua tab sis ruaj khov uas muab kev rwb thaiv tsev zoo heev. Nws cov yam ntxwv zoo kawg nkaus ua rau EVA ua npuas ncauj yog cov khoom siv ntau yam, siv dav hauv cov khoom siv niaj hnub thiab cov ntawv thov tshwj xeeb hauv ntau yam lag luam, xws li khau hauv qab, cov lev ua npuas ncauj mos, cov thaiv yoga, cov rooj ua luam dej, hauv pem teb, thiab lwm yam.

2. Cov Kev Txwv ntawm Cov Ua Npuas Ncauj EVA Ib Txwm Muaj Yog Dab Tsi?

Muaj ntau tus neeg xav tias cov khoom siv EVA ua npuas ncauj yog qhov sib xyaw ua ke zoo meej ntawm lub plhaub tawv thiab lub plhaub mos, Txawm li cas los xij, kev siv cov khoom siv EVA ua npuas ncauj tsuas yog txwv rau qee qhov vim nws tsis zoo rau kev laus, kev ua haujlwm flexure, elasticity, thiab kev ua haujlwm abrasion. Kev nce ntawm ETPU nyob rau xyoo tas los no thiab kev sib piv ntawm cov qauv kuj ua rau EVA ua npuas ncauj khau yuav tsum muaj qhov nyuaj qis dua, rov qab siab dua, qis compression deformation, thiab lwm yam khoom tshiab.

Tsis tas li ntawd xwb, Kev Sib Tw Ib Puag Ncig thiab Kev Noj Qab Haus Huv ntawm EVA Ua Npuas Ncauj Ntau Lawm.

Cov khoom ua npuas dej EVA uas muaj nyob rau hauv kev ua lag luam tam sim no yog npaj los ntawm txoj kev ua npuas dej tshuaj thiab feem ntau yog siv rau cov khoom xws li cov khoom siv khau, cov ntaub pua plag hauv av, thiab lwm yam uas sib cuag ncaj qha nrog tib neeg lub cev. Txawm li cas los xij, cov khoom ua npuas dej EVA uas npaj los ntawm txoj kev thiab cov txheej txheem muaj ntau yam kev tiv thaiv ib puag ncig thiab teeb meem kev noj qab haus huv, thiab tshwj xeeb tshaj yog, cov tshuaj lom neeg (tshwj xeeb tshaj yog formamide) raug sib cais tas li ntawm sab hauv ntawm cov khoom ntev.