Kev Taw Qhia:

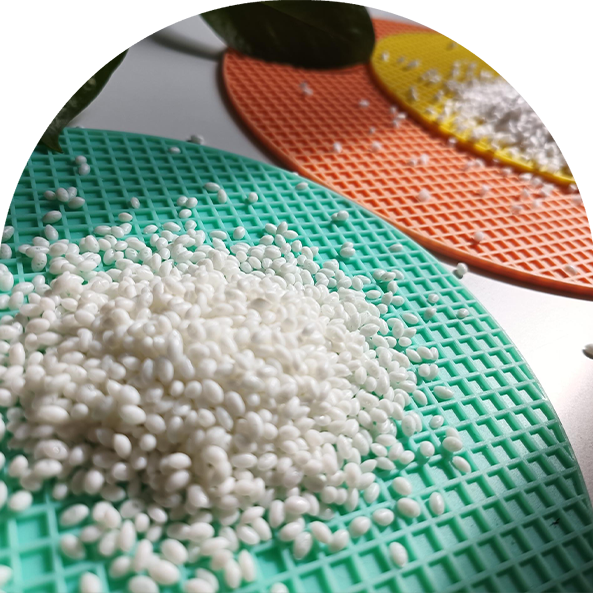

Hauv ntiaj teb ntawm kev tshawb fawb txog cov ntaub ntawv thiab kev tsim kho, feem ntau muaj kev hloov pauv tshiab uas cog lus tias yuav hloov pauv kev lag luam thiab hloov kho txoj hauv kev uas peb tsim thiab tsim khoom. Ib qho kev hloov pauv tshiab no yog kev tsim kho thiab kev siv cov dynamic vulcanizate thermoplastic Silicone-based elastomer (feem ntau luv rau Si-TPV), ib yam khoom siv tau ntau yam uas muaj peev xwm hloov TPE, TPU, thiab silicone ib txwm muaj rau ntau yam kev siv.

Si-TPV muaj ib qho chaw uas muaj qhov kov zoo nkauj thiab zoo rau daim tawv nqaij, tiv taus cov av zoo heev, tiv taus khawb zoo dua, tsis muaj cov roj plasticizer thiab cov roj mos, tsis muaj kev pheej hmoo ntawm kev los ntshav / nplaum, thiab tsis muaj ntxhiab tsw, uas ua rau nws yog lwm txoj hauv kev zoo rau TPE, TPU, thiab silicone hauv ntau qhov xwm txheej, los ntawm cov khoom siv rau cov neeg siv khoom mus rau kev siv hauv kev lag luam.

Yuav kom paub tseeb tias Si-TPVs siv tau hloov TPE, TPU, thiab silicone thaum twg, peb yuav tsum tshuaj xyuas lawv cov khoom, kev siv, thiab qhov zoo. Hauv tsab xov xwm no, saib ua ntej nkag siab txog Si-TPV thiab TPE!

Kev Tshawb Fawb Sib Piv ntawm TPE & Si-TPV

1.TPE (Thermoplastic Elastomers):

TPEs yog ib chav kawm ntawm cov ntaub ntawv siv tau ntau yam uas sib xyaw cov yam ntxwv ntawm thermoplastics thiab elastomers.

Lawv paub txog lawv qhov yooj ywm, lub zog rov qab, thiab yooj yim ua tiav.

TPEs muaj ntau hom subtypes, xws li TPE-S (Styrenic), TPE-O (Olefinic), thiab TPE-U (Urethane), txhua tus muaj cov yam ntxwv sib txawv.

2.Si-TPV (dynamic vulcanizate thermoplastic Silicone-based elastomer):

Si-TPV yog ib qho khoom tshiab nkag mus rau hauv kev lag luam elastomer, sib xyaw cov txiaj ntsig ntawm cov roj hmab silicone thiab cov thermoplastics.

Nws muaj kev tiv taus cua sov, UV hluav taws xob, thiab tshuaj lom neeg zoo heev, Si-TPV tuaj yeem ua tiav siv cov txheej txheem thermoplastic txheem xws li kev txhaj tshuaj molding thiab extrusion.

Thaum Twg Si-TPV Thiaj Siv Tau Lwm Txoj Hauv Kev TPE?

1. Cov Ntawv Thov Kub Siab

Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm Si-TPV dua li feem ntau TPEs yog nws qhov kev tiv taus kub siab heev. TPEs tuaj yeem ua rau mos lossis poob lawv cov khoom elastic thaum kub siab, txwv lawv qhov kev tsim nyog rau cov ntawv thov uas qhov kev tiv taus kub tseem ceeb heev. Si-TPV ntawm qhov tod tes, tswj nws qhov kev ywj pheej thiab kev ncaj ncees txawm tias thaum kub heev, ua rau nws yog qhov hloov pauv zoo tagnrho rau TPE hauv cov ntawv thov xws li cov khoom siv tsheb, cov tes tuav ua noj, thiab cov khoom siv hauv kev lag luam uas raug cua sov.

2. Kev Tiv Thaiv Tshuaj

Si-TPV ua pov thawj tias nws tiv taus cov tshuaj lom neeg, roj, thiab cov kuab tshuaj zoo dua li ntau hom TPE. Qhov no ua rau nws yog qhov kev xaiv zoo rau cov ntawv thov uas xav tau kev raug rau cov chaw muaj tshuaj lom neeg hnyav, xws li cov foob, gaskets, thiab cov hoses hauv cov khoom siv ua tshuaj lom neeg. TPEs yuav tsis muab tib theem ntawm kev tiv taus tshuaj lom neeg hauv cov xwm txheej zoo li no.

3. Kev Ruaj Khov thiab Kev Tiv Thaiv Huab Cua

Nyob rau sab nraum zoov thiab tej yam kev mob hnyav, Si-TPV ua tau zoo dua TPEs hauv kev ruaj khov thiab huab cua. Si-TPV txoj kev tiv thaiv rau UV hluav taws xob thiab huab cua ua rau nws yog qhov kev xaiv zoo rau kev siv sab nraum zoov, suav nrog cov foob thiab gaskets hauv kev tsim kho, kev ua liaj ua teb, thiab cov khoom siv hauv hiav txwv. TPEs tuaj yeem lwj lossis poob lawv cov khoom thaum raug tshav ntuj ntev thiab tej yam ib puag ncig.

4. Kev sib haum xeeb ntawm lub cev

Rau kev siv kho mob thiab kev kho mob, kev sib haum xeeb ntawm lub cev yog qhov tseem ceeb. Txawm hais tias qee cov qauv TPE yog biocompatible, Si-TPV muaj kev sib xyaw ua ke ntawm kev sib haum xeeb ntawm lub cev thiab kev tiv taus kub tshwj xeeb, ua rau nws yog qhov kev xaiv zoo rau cov khoom xws li cov raj kho mob thiab cov ntsaws ruaj ruaj uas xav tau ob qho tib si.

5. Kev Rov Ua Dua thiab Kev Siv Dua

Si-TPV lub thermoplastic xwm txheej tso cai rau kev rov ua dua thiab rov ua dua tshiab yooj yim dua piv rau TPEs. Qhov no sib haum nrog lub hom phiaj kev ruaj khov thiab txo cov khoom pov tseg, ua rau Si-TPV yog qhov kev xaiv zoo rau cov tuam txhab tsim khoom uas tsom mus rau kev txo lawv cov teeb meem ib puag ncig.

Xaus lus:

Thaum nrhiav TPE, nws yog ib lub tswv yim zoo los tshawb nrhiav thiab txheeb xyuas cov khoom lag luam Si-TPV tam sim no !!

Txawm hais tias TPEs tau siv dav hauv ntau daim ntawv thov vim lawv qhov ua tau ntau yam. Txawm li cas los xij, Si-TPV qhov kev tshwm sim tau qhia txog lwm txoj hauv kev zoo, tshwj xeeb tshaj yog nyob rau hauv cov xwm txheej uas qhov kub siab tiv taus, tshuaj lom neeg tiv taus, thiab kev ruaj khov yog qhov tseem ceeb. Si-TPV qhov kev sib xyaw ua ke ntawm cov khoom ua rau nws yog tus neeg sib tw muaj zog los hloov TPEs hauv ntau yam lag luam, los ntawm tsheb thiab kev lag luam mus rau kev kho mob thiab kev siv sab nraum zoov. Raws li kev tshawb fawb thiab kev txhim kho hauv kev tshawb fawb txog cov ntaub ntawv txuas ntxiv mus, Si-TPV lub luag haujlwm hauv kev hloov TPEs yuav nthuav dav, muab cov chaw tsim khoom ntau txoj hauv kev los txhim kho lawv cov khoom rau cov kev xav tau tshwj xeeb.