Yog dab tsiNylon Overmolding?

Nylon overmolding, tseem hu ua nylon ob-shot molding lossis insert molding, yog ib txoj kev tsim khoom siv los tsim cov khoom siv nrog ntau yam khoom siv. Feem ntau nws cuam tshuam nrog kev txhaj tshuaj nylon molten hla ib qho substrate uas tau tsim ua ntej, xws li yas, hlau, lossis lwm yam khoom siv, los tsim ib qho khoom sib xyaw ua ke. Cov txheej txheem no tso cai rau kev sib xyaw ua ke ntawm cov khoom sib txawv nrog cov yam ntxwv sib txawv, ua rau cov khoom uas muaj kev ua haujlwm zoo dua thiab kev ua tau zoo.

Cov teeb meem hauv Nylon Overmolding:

1. Teeb Meem Kev Sib Txuas: Kev ua kom cov nylon thiab cov khoom siv substrate sib txuas tau zoo tuaj yeem nyuaj, tshwj xeeb tshaj yog thaum cov substrate muaj qhov chaw du lossis tsis muaj qhov, thiab thaum ua haujlwm nrog cov khoom sib txawv. Kev sib txuas tsis zoo tuaj yeem ua rau tawg, ua rau ib feem puas tsuaj, thiab txo qhov ruaj khov.

2. Kev Ntsws thiab Kev Ntsws: Nylon feem ntau yuav ntsws thiab ntsws thaum lub sijhawm molding, uas tuaj yeem ua rau muaj qhov tsis raug ntawm qhov ntev thiab qhov tsis zoo ntawm cov khoom kawg. Qhov teeb meem no feem ntau tshwm sim hauv cov khoom loj lossis nyuaj.

3. Kev Sib Xws ntawm Cov Khoom Siv: Tej teeb meem sib xws yuav tshwm sim thaum muab nylon rau ntawm qee cov substrates, ua rau kev sib txuas tsis ua haujlwm, lossis cov khoom puas tsuaj thiab qhov tsis zoo ntawm qhov chaw. Nws yog ib qho tseem ceeb uas yuav tsum xaiv cov khoom siv sib xws thiab kev kho qhov chaw kom zoo kom ntseeg tau tias kev sib xyaw ua ke zoo.

4. Tus nqi: Nylon overmolding tuaj yeem kim dua li cov txheej txheem molding ib txwm muaj, tshwj xeeb tshaj yog thaum xav txog cov nqi khoom siv, cov nqi cuab yeej, thiab lub sijhawm tsim khoom.

Cov Kev Daws Teeb Meem Kom Kov Yeej Cov Kev Cov Nylon Overmolding:

1. Kev Npaj Qhov Chaw: Kev npaj qhov chaw kom zoo yog qhov tseem ceeb kom ntseeg tau tias cov nylon thiab cov khoom siv substrate lo rau zoo. Qhov no yuav suav nrog kev ntxuav, pleev xim, lossis ua kom qhov chaw substrate ntxhib kom txhawb kev sib txuas. Cov txheej txheem xws li kev ua kom qhov chaw ntxhib, kev siv tshuaj etching, lossis kev kho plasma tuaj yeem txhim kho kev sib txuas ntawm nylon thiab cov khoom siv substrate.

2. Kev Tsim Qauv Pwm Zoo: Kev tsim qauv pwm zoo tuaj yeem pab txo qhov teeb meem warping thiab shrinkage cuam tshuam nrog nylon. Cov yam ntxwv xws li phab ntsa tuab sib npaug, cov channel txias txaus, thiab lub kaum sab xis tuaj yeem pab tswj kev shrinkage thiab txo cov kev ntxhov siab sab hauv.

3. Kev Xaiv Khoom Siv: Kev xaiv cov nylon qib thiab cov khoom siv substrate yog qhov tseem ceeb rau kev ua kom sib xws thiab ua tiav cov yam ntxwv kev ua tau zoo. Kev ua qhov kev sim sib xws ntawm cov khoom siv thiab kev xaiv cov khoom siv uas muaj cov coefficients zoo sib xws ntawm kev nthuav dav thermal tuaj yeem txo cov teeb meem uas yuav tshwm sim.

4. Kev Txhim Kho Cov Txheej Txheem: Kev kho kom zoo dua cov txheej txheem molding, xws li qhov kub, siab, thiab lub sijhawm voj voog, tuaj yeem ua kom zoo dua cov txheej txheem overmolding thiab txhim kho qhov zoo ntawm qhov khoom. Cov txheej txheem molding siab heev, xws li kev txhaj tshuaj molding uas pab los ntawm roj, kuj tseem siv tau los txo qhov warping thiab shrinkage.

5. Kev Tswj Xyuas Zoo: Kev siv cov kev tswj xyuas zoo nruj thoob plaws hauv cov txheej txheem tsim khoom tuaj yeem pab txheeb xyuas thiab daws cov teeb meem thaum ntxov. Kev tshuaj xyuas tsis tu ncua ntawm cov khoom pwm, kev kuaj xyuas qhov tseeb ntawm qhov loj me, thiab kev sim ua haujlwm tuaj yeem ua kom ntseeg tau tias cov khoom kawg ua tau raws li cov lus qhia xav tau.

Kev Qhib Kev Tsim Kho Tshiab: Si-TPV Txhawb Kom Cov Chaw Tsim Khoom Ua Tau Zoo Hauv Kev Sib Tw Nylon Overmolding

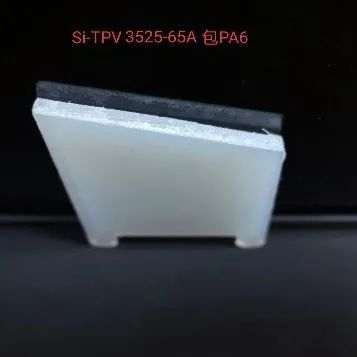

Si-TPV yog ib qho dynamic vulcanizate thermoplastic elastomer uas muab cov yam ntxwv zoo tshaj plaws ntawm silicone roj hmab thiab thermoplastic polymers. Cov khoom siv tshiab no muaj kev sib xyaw ua ke ntawm kev mos, kev ywj pheej, thiab kev ruaj khov, ua rau nws zoo tagnrho rau ntau yam kev siv overmolding. Tsis zoo li cov ntaub ntawv ib txwm muaj, Si-TPV muaj kev vulcanization dynamic, uas ua rau muaj cov khoom siv kho tshuab zoo dua thiab kev nplaum zoo heev rau nylon substrates.

Cov txiaj ntsig tseem ceeb ntawm Si-TPV rau Nylon Overmolding:

Kev Mos Mos Uas Tsis Muaj Qhov Sib Piv: Si-TPV muab qhov mos mos thiab zoo li lub ncoo rau cov khoom uas raug pwm, ua kom tus neeg siv xis nyob thiab ergonomics zoo dua. Nws qhov kev ywj pheej zoo tshaj plaws tso cai rau kev tsim cov duab thiab cov duab sib txawv, ua rau cov neeg tsim qauv tso tawm lawv txoj kev muaj tswv yim.

Kev Nplaum Zoo Kawg Nkaus: Si-TPV ua rau pom kev nplaum zoo heev rau cov nylon substrates, ua kom muaj kev sib txuas zoo thiab ruaj khov hauv cov khoom uas raug pwm ntau dhau. Qhov no tshem tawm qhov kev pheej hmoo ntawm kev tawg lossis sib cais, txawm tias nyob rau hauv cov ntawv thov uas nyuaj.

Kev Ruaj Khov Zoo Dua: Si-TPV muaj kev tiv thaiv zoo heev rau kev hnav, tsim kua muag, thiab tej yam ib puag ncig, ua kom muaj kev ua tau zoo thiab kev ntseeg siab mus sij hawm ntev hauv tej yam mob hnyav.

Kev Siv Tau Ntau Yam: Si-TPV sib xws nrog ntau yam nylon qib thiab cov txheej txheem ua haujlwm, ua rau nws haum rau ntau yam kev siv overmolding thoob plaws kev lag luam.

Zoo nkauj heev: Si-TPV ua rau cov khoom uas raug pwm zoo nkauj dua vim nws du thiab xim ci ntsa iab. Nws lub peev xwm khaws cov qauv thiab cov ntsiab lus ntxiv rau qhov zoo nkauj ntawm cov khoom kawg.

Cov ntawv thov ntawm Si-TPV hauv Nylon Overmolding:

Si-TPV pom muaj ntau daim ntawv thov hauv ntau yam lag luam, suav nrog tsheb, khoom siv hluav taws xob, khoom siv rau cov neeg siv khoom, cov khoom siv kho mob, thiab ntau ntxiv. Qee qhov kev siv dav suav nrog:

Cov khoom siv sab hauv tsheb xws li cov chaw kov mos mos, cov chaw so tes, thiab cov tes tuav

Cov khoom siv hluav taws xob rau cov neeg siv khoom xws li cov hnab xov tooj, cov npog mloog pob ntseg, thiab cov chaw taws teeb tswj

Cov khoom siv kho mob uas xav tau cov ntaub ntawv mos mos thiab biocompatible

Cov khoom siv kis las thiab cov khoom siv nrog ergonomic grips thiab cushioning

Xaus lus:Si-TPV qhib cov cib fim tshiab rau cov neeg tsim qauv thiab cov chaw tsim khoom uas tab tom nrhiav kev tsim cov khoom lag luam zoo thiab tshiab. Txawm hais tias koj tab tom nrhiav kev txhim kho kev nplij siab rau tus neeg siv, txhim kho kev zoo nkauj ntawm cov khoom, daws teeb meem kev sib txuas, daws teeb meem warping thiab Shrinkage, lossis ua kom zoo dua cov txheej txheem tsim khoom, Si-TPV yog qhov kev xaiv zoo tshaj plaws rau koj cov kev xav tau nylon overmolding.

Tsis Txhob Cia Tej Kev Cov Nyom Ua Rau Koj Tsis Muaj Zog! Txais yuav lub zog ntawm Si-TPV thiab qhib cov cib fim tshiab rau kev vam meej hauv nylon overmolding. Hu rau SILIKE tam sim no kom paub ntau ntxiv txog kev tsa koj cov txheej txheem nylon overmolding mus rau qhov siab tshiab ntawm kev ua tau zoo thiab kev ua haujlwm zoo.

Xov tooj: +86-28-83625089 los yog +86-15108280799

Email: amy.wang@silike.cn

Lub Vas Sab Hauv Internet: www.si-tpv.com