Kev Qhia Txog

Cov khoom siv yog cov khoom siv los ua kom tau cov khoom, tus nqa khoom siv thev naus laus zis thiab kev ua haujlwm, thiab tus neeg nruab nrab ntawm kev sib txuas lus ntawm tib neeg thiab cov khoom. Rau cov khoom zaws, kev tsim kho tshiab ntawm cov khoom siv feem ntau yog kev siv cov khoom siv tshiab, uas yog, cov khoom siv tshiab rau lub sijhawm zoo, tsim nyog rau cov khoom siv zaws tshiab. Kev siv cov ntaub ntawv tshawb fawb thiab thev naus laus zis tshiab ntawm cov khoom ib txwm yuav nthuav tawm cov duab tshiab, muab rau tib neeg qhov kev xav pom thiab kev xav kov, kom ua tiav kev pabcuam zoo dua rau tib neeg.

Cov Txiaj Ntsig Tseem Ceeb

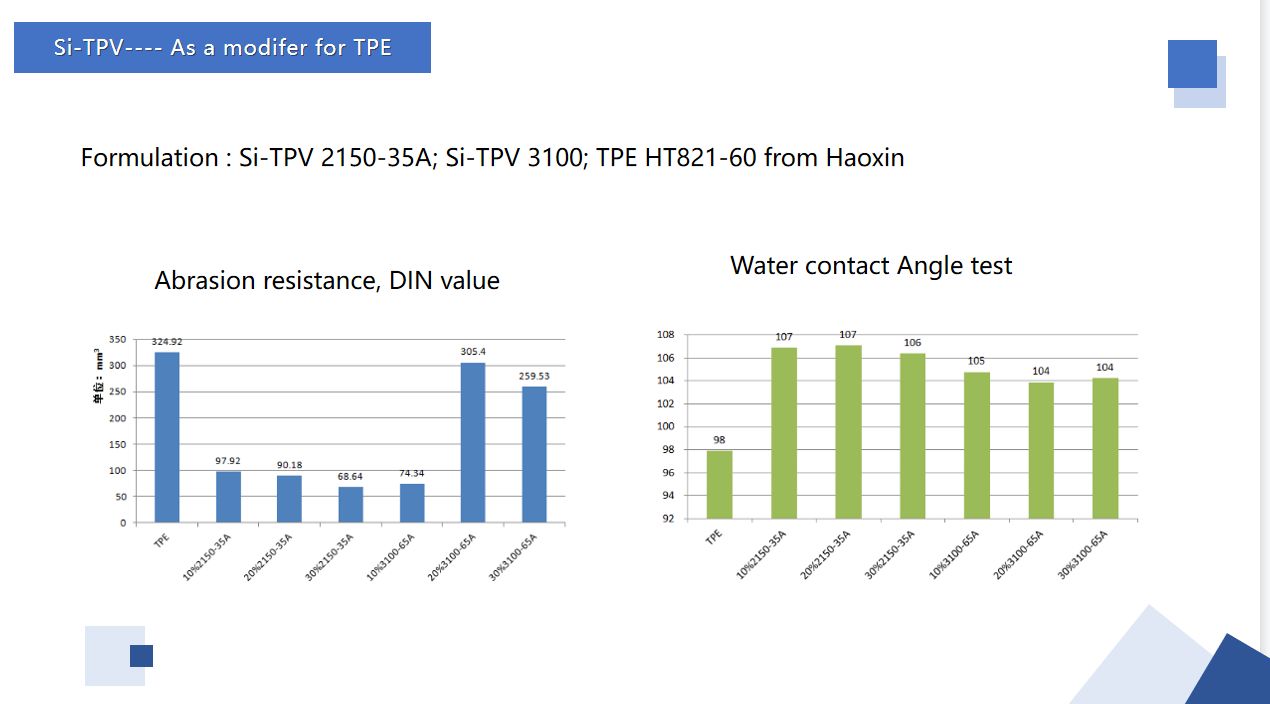

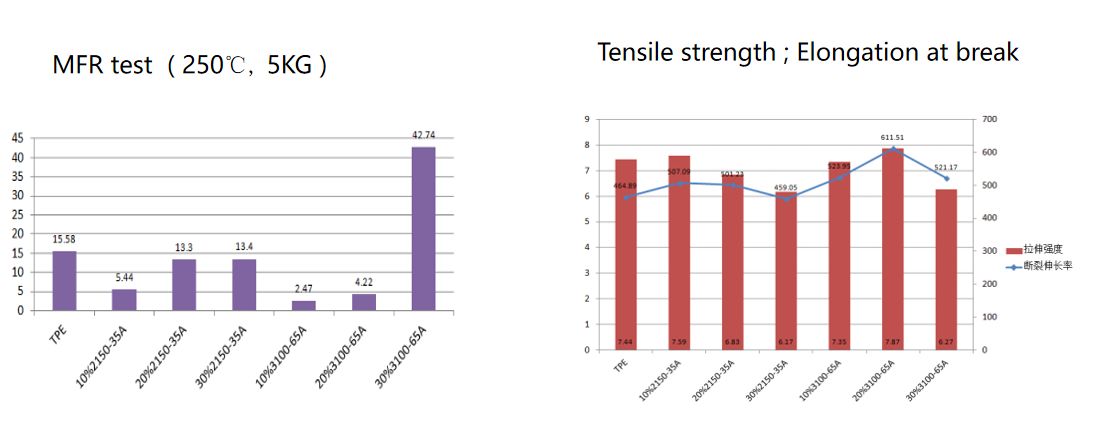

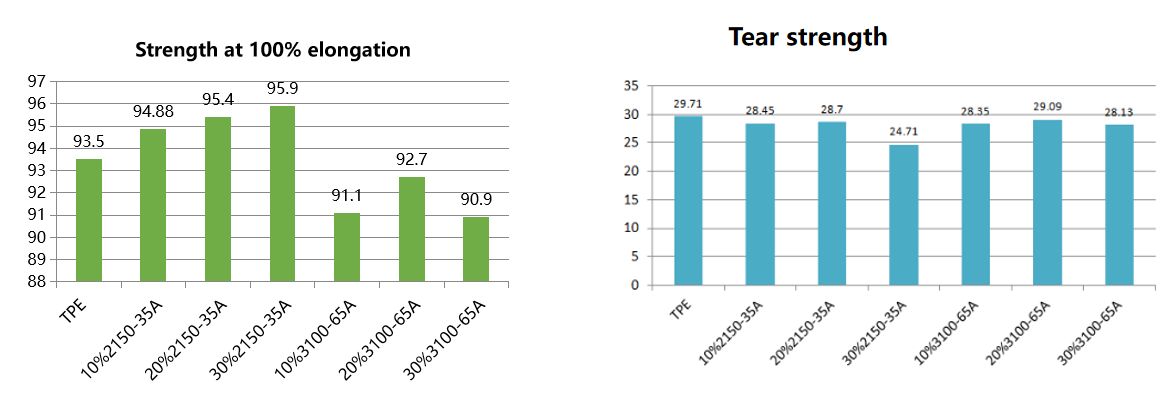

- Hauv TPE

- 1. Kev tiv thaiv kev sib txhuam

- 2. Tiv thaiv cov xim av nrog lub kaum sab xis me dua rau kev sib cuag dej

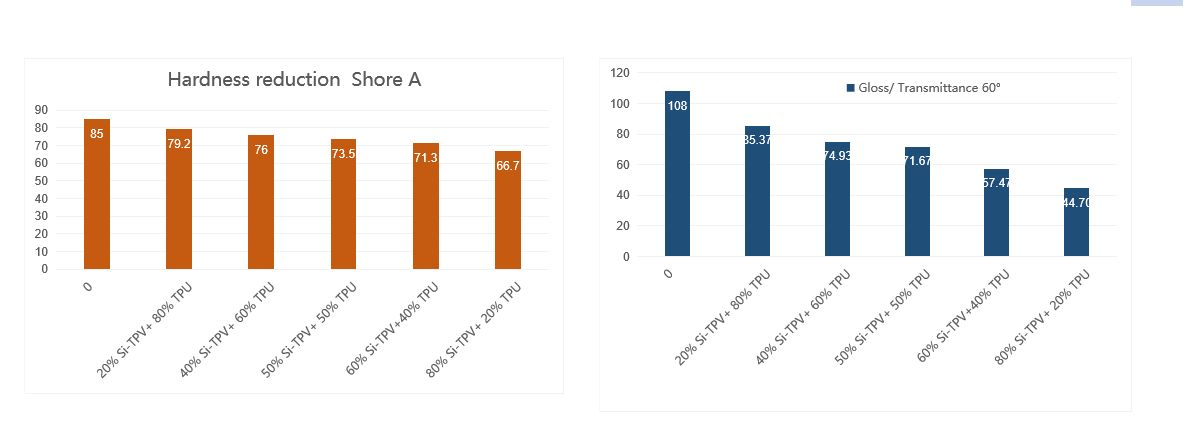

- 3. Txo qhov nyuaj

- 4. Yuav luag tsis muaj kev cuam tshuam rau cov khoom siv kho tshuab nrog peb cov Si-TPV 2150 series

- 5. Zoo haptics, qhuav silky kov, tsis muaj blooming tom qab siv ntev

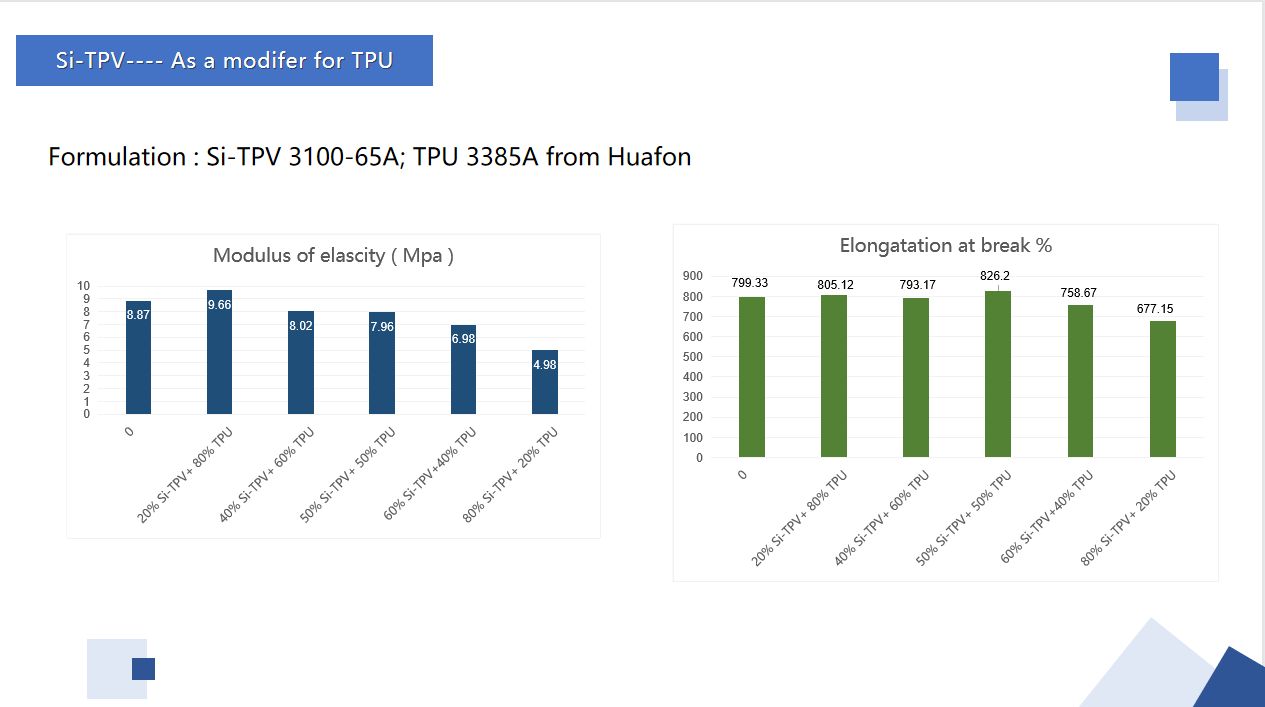

- Hauv TPU

- 1. Kev txo qhov nyuaj

- 2. Zoo haptics, qhuav silky kov, tsis muaj blooming tom qab siv ntev

- 3. Muab cov khoom TPU kawg nrog qhov chaw zoo nkauj

- 4. Me ntsis cuam tshuam rau cov khoom siv kho tshuab yog tias qhov ntxiv ntawm ntau tshaj 20%

Kev Ruaj Khov Kev Ruaj Khov

- Cov thev naus laus zis tsis muaj kuab tshuaj, tsis muaj plasticizer, tsis muaj roj softening, thiab tsis muaj ntxhiab.

- Kev tiv thaiv ib puag ncig thiab kev siv rov qab tau.

- Muaj nyob rau hauv cov qauv tsim uas ua raws li txoj cai

Si-TPV raws li kev hloov pauv & txheej txheem kev qhia ntxiv

Si-TPV 2150 series muaj cov yam ntxwv ntawm kev kov mos mos rau daim tawv nqaij ntev, tiv taus cov av zoo, tsis muaj plasticizer thiab softener ntxiv, thiab tsis muaj nag tom qab siv ntev, tshwj xeeb tshaj yog siv rau kev npaj cov thermoplastic elastomers uas zoo nkauj thiab xis nyob.

Daim Ntawv Thov

Thaum xaiv Si-TPV rau kev siv overmolding, yuav tsum xav txog hom substrate. Tsis yog txhua Si-TPV yuav sib txuas rau txhua hom substrates. Ntxiv nrog rau kev siv Si-TPV overmolds ntawm lub taub hau ntawm lub tshuab zaws, nws yog ib lub tswv yim zoo los siv Si-TPV overmolds ntawm lub cev ntawm lub cuab yeej lossis ntawm cov nyees khawm - txhua qhov chaw uas muaj kev sib cuag ntawm daim tawv nqaij, Si-TPV taug qab TPE overmolds tuaj yeem ua qhov sib txawv. Cov ntawv thov tshwj xeeb tuaj yeem suav nrog lub xub pwg nyom thiab caj dab zaws, lub ntsej muag zaws, lub taub hau zaws, thiab lwm yam.

Cov khoom siv zaws uas tsis yog tshuab thaum ub yog ntoo, qee cov khoom siv zaws tshuab lub taub hau zaws kuj yog ntoo. Thiab tam sim no nws feem ntau hloov mus siv cov khoom siv silicone ua cov khoom siv npog ntawm cov cuab yeej zaws. Piv nrog rau lub taub hau zaws ntoo, silicone yog softer thiab tiv taus kub siab dua, tab sis nws qhov kov ntawm daim tawv nqaij yuav tsum tau ua raws li kev kho mob txheej, uas ua rau muaj kev nyuaj rau ib puag ncig, thiab kev siv mus sij hawm ntev yuav raug cuam tshuam los ntawm txheej tawm ntawm qhov kov.

Niaj hnub no, nrog rau kev muaj ntau yam khoom siv thiab kev txhim kho tas mus li ntawm cov thev naus laus zis, kev xaiv thiab kev siv cov khoom siv tau los ua qhov tseem ceeb dua hauv kev tsim khoom. Koj xaiv cov khoom siv txheej uas muab kev ywj pheej mos mos thiab ua rau daim tawv nqaij zoo, du li cas?

Kev Dais Teeb Meem Mos: Txhim Kho Kev Xis Nyob Los Ntawm Kev Tsim Kho Tshiab Overmolding>>