Kev Qhia Txog

Cov SILIKE Si-TPV 2150 Series yog ib qho dynamic vulcanizate silicone-based elastomer, tsim los ntawm kev siv cov thev naus laus zis sib xws. Cov txheej txheem no faib cov roj hmab silicone rau hauv SEBS ua cov khoom me me, xws li 1 txog 3 microns hauv qab lub tshuab microscope. Cov ntaub ntawv tshwj xeeb no ua ke lub zog, kev tawv, thiab kev tiv thaiv kev sib txhuam ntawm cov thermoplastic elastomers nrog cov khoom zoo ntawm silicone, xws li kev mos, kev xav zoo nkauj, thiab kev tiv thaiv UV lub teeb thiab cov tshuaj lom neeg. Tsis tas li ntawd, cov ntaub ntawv Si-TPV yog cov khoom siv rov ua dua tshiab thiab tuaj yeem siv dua hauv cov txheej txheem tsim khoom ib txwm muaj.

Si-TPV siv tau ncaj qha ua cov khoom siv raw, tsim tshwj xeeb rau kev siv cov khoom siv kov mos mos hauv cov khoom siv hluav taws xob hnav tau, cov thawv tiv thaiv rau cov khoom siv hluav taws xob, cov khoom siv tsheb, cov TPEs siab, thiab cov lag luam hlau TPE.

Ntxiv rau nws txoj kev siv ncaj qha, Si-TPV kuj tseem tuaj yeem ua haujlwm ua tus hloov kho polymer thiab cov txheej txheem ntxiv rau thermoplastic elastomers lossis lwm yam polymers. Nws txhim kho elasticity, txhim kho kev ua tiav, thiab txhawb cov khoom ntawm qhov chaw. Thaum sib xyaw nrog TPE lossis TPU, Si-TPV muab qhov du ntawm qhov chaw ntev thiab qhov kev xav zoo siab, thaum tseem txhim kho kev khawb thiab kev puas tsuaj. Nws txo qhov nyuaj yam tsis muaj kev cuam tshuam tsis zoo rau cov khoom siv kho tshuab thiab muab kev laus zoo dua, daj, thiab kev tiv thaiv xim. Nws kuj tseem tuaj yeem tsim kom muaj qhov tiav matte zoo rau ntawm qhov chaw.

Tsis zoo li cov tshuaj ntxiv silicone ib txwm muaj, Si-TPV muab rau hauv daim ntawv pellet thiab ua tiav zoo li thermoplastic. Nws tawg zoo thiab sib npaug thoob plaws hauv cov polymer matrix, nrog rau cov copolymer ua lub cev khi rau lub matrix. Qhov no tshem tawm qhov kev txhawj xeeb ntawm kev tsiv teb tsaws chaw lossis "blooming" teeb meem, ua rau Si-TPV yog qhov kev daws teeb meem zoo thiab tshiab rau kev ua tiav cov nplaim mos mos hauv thermoplastic elastomers lossis lwm yam polymers. thiab tsis xav tau cov txheej txheem ua tiav lossis txheej ntxiv.

Cov Txiaj Ntsig Tseem Ceeb

- Hauv TPE

- 1. Kev tiv thaiv kev sib txhuam

- 2. Tiv thaiv cov xim av nrog lub kaum sab xis me dua rau kev sib cuag dej

- 3. Txo qhov nyuaj

- 4. Yuav luag tsis muaj kev cuam tshuam rau cov khoom siv kho tshuab nrog peb cov Si-TPV 2150 series

- 5. Zoo haptics, qhuav silky kov, tsis muaj blooming tom qab siv ntev

Kev Ruaj Khov Kev Ruaj Khov

- Cov thev naus laus zis tsis muaj kuab tshuaj, tsis muaj plasticizer, tsis muaj roj softening, thiab tsis muaj ntxhiab.

- Kev tiv thaiv ib puag ncig thiab kev siv rov qab tau.

- Muaj nyob rau hauv cov qauv tsim uas ua raws li kev cai lij choj.

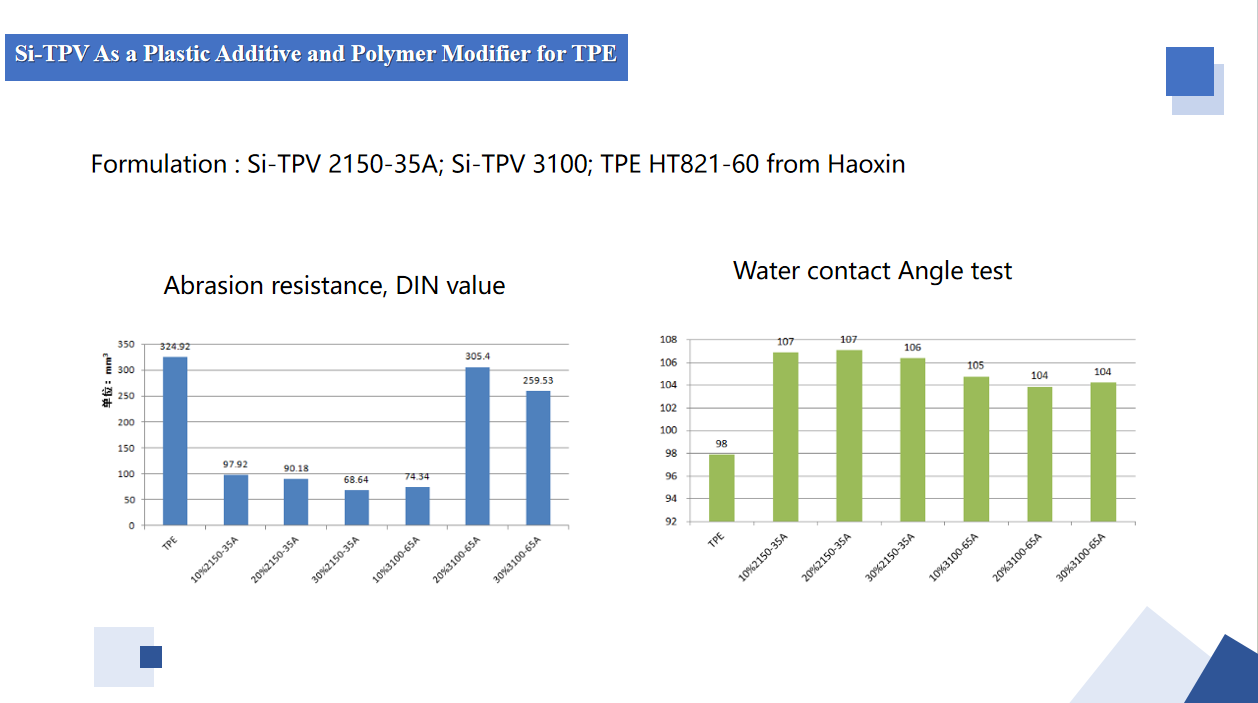

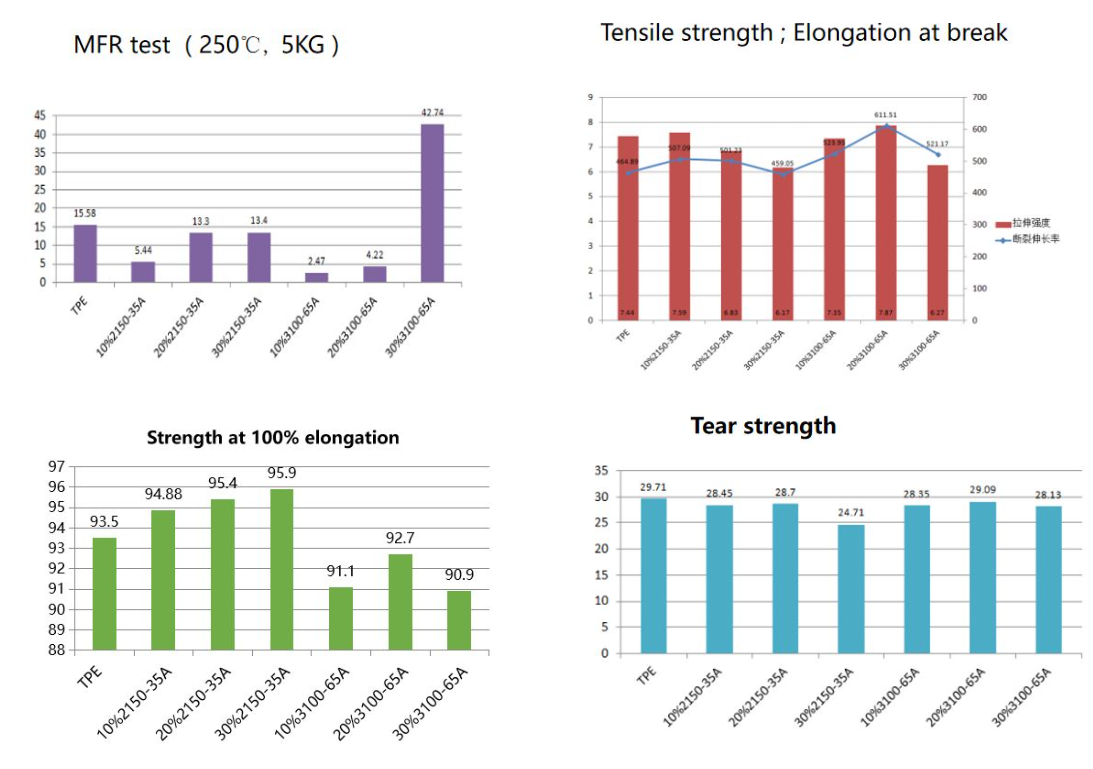

Cov Kev Kawm Txog Si-TPV yas additive thiab polymer modifier

Si-TPV 2150 series muaj cov yam ntxwv ntawm kev kov mos mos rau daim tawv nqaij ntev, tiv taus cov xim zoo, tsis muaj plasticizer thiab softener ntxiv, thiab tsis muaj nag tom qab siv ntev, uas ua haujlwm ua cov yas ntxiv thiab polymer modifier, tshwj xeeb tshaj yog siv rau kev npaj thermoplastic elastomers uas zoo nkauj thiab xis.

Kev Sib Piv Cov Nyhuv ntawm Si-TPV Yas Additive thiab Polymer Modifier rau TPE Kev Ua Haujlwm

Daim Ntawv Thov

Si-TPV ua haujlwm ua ib qho kev hloov kho tshiab thiab cov khoom siv ua tiav rau cov thermoplastic elastomers thiab lwm yam polymers. Nws tuaj yeem sib xyaw nrog ntau yam elastomers thiab engineering lossis dav dav plastics, xws li TPE, TPU, SEBS, PP, PE, COPE, EVA, ABS, thiab PVC. Cov kev daws teeb meem no pab txhim kho kev ua haujlwm zoo thiab txhim kho kev ua haujlwm khawb thiab kev tiv thaiv kev sib txhuam ntawm cov khoom tiav.

Ib qho txiaj ntsig tseem ceeb ntawm cov khoom ua los ntawm TPE thiab Si-TPV sib xyaw yog kev tsim kom muaj qhov chaw mos mos uas tsis nplaum - qhov kev paub kov uas cov neeg siv khoom xav tau los ntawm cov khoom uas lawv feem ntau kov lossis hnav. Qhov tshwj xeeb no ua rau ntau yam kev siv rau TPE elastomer cov ntaub ntawv thoob plaws ntau yam lag luam. Ntxiv mus, kev siv Si-TPV ua tus hloov kho ua rau muaj kev ywj pheej, elasticity, thiab kev ruaj khov ntawm cov ntaub ntawv elastomer, thaum ua rau cov txheej txheem tsim khoom pheej yig dua.

Cov Kev Daws Teeb Meem:

Puas Muaj Teeb Meem Los Txhawb Kev Ua Haujlwm TPE? Si-TPV Yas Additives thiab polymer modifiers Muab Cov Lus Teb

Kev Taw Qhia Txog TPEs

Cov thermoplastic elastomers (TPEs) raug faib ua pawg raws li cov tshuaj lom neeg sib xyaw, suav nrog Thermoplastic Olefins (TPE-O), Styrenic Compounds (TPE-S), Thermoplastic Vulcanizates (TPE-V), Polyurethanes (TPE-U), Copolyesters (COPE), thiab Copolyamides (COPA). Txawm hais tias polyurethanes thiab copolyesters yuav raug tsim ntau dhau rau qee qhov kev siv, cov kev xaiv pheej yig dua xws li TPE-S thiab TPE-V feem ntau muab qhov haum zoo dua rau cov ntawv thov.

Cov TPE ib txwm muaj yog cov roj hmab thiab cov thermoplastics sib xyaw ua ke, tab sis TPE-Vs txawv los ntawm kev muaj cov roj hmab uas sib txuas ua ke ib feem lossis tag nrho, ua rau lawv ua tau zoo dua. TPE-Vs muaj cov khoom sib dhos qis dua, tiv taus tshuaj lom neeg thiab kev sib txhuam zoo dua, thiab ruaj khov dua qhov kub thiab txias, ua rau lawv zoo tagnrho rau kev hloov roj hmab hauv cov foob. Qhov sib piv, cov TPE ib txwm muaj kev ywj pheej ntau dua, lub zog tensile siab dua, elasticity, thiab xim, ua rau lawv haum rau cov khoom xws li cov khoom siv rau cov neeg siv khoom, cov khoom siv hluav taws xob, thiab cov khoom siv kho mob. Lawv kuj tseem sib txuas zoo rau cov khoom siv tawv xws li PC, ABS, HIPS, thiab Nylon, uas yog qhov zoo rau cov ntawv thov mos mos.

Cov teeb meem nrog TPEs

TPEs muab kev ywj pheej nrog lub zog kho tshuab thiab kev ua haujlwm tau zoo, ua rau lawv muaj ntau yam siv tau. Lawv cov khoom ywj pheej, xws li kev teeb tsa compression thiab elongation, los ntawm theem elastomer, thaum lub zog tensile thiab tear strength nyob ntawm cov khoom yas.

TPEs tuaj yeem ua tiav zoo li cov thermoplastics ib txwm muaj ntawm qhov kub siab, qhov twg lawv nkag mus rau theem yaj, ua rau muaj kev tsim khoom zoo siv cov khoom siv ua yas txheem. Lawv qhov kub ua haujlwm kuj tseem ceeb, txuas ntxiv los ntawm qhov kub qis heev - ze rau qhov hloov pauv iav ntawm theem elastomer - mus rau qhov kub siab ze rau qhov yaj ntawm theem thermoplastic - ntxiv rau lawv qhov kev hloov pauv tau yooj yim.

Txawm li cas los xij, txawm hais tias muaj cov txiaj ntsig no, ntau yam teeb meem tseem muaj nyob rau hauv kev ua kom zoo dua ntawm TPEs. Ib qho teeb meem loj yog qhov nyuaj hauv kev sib npaug ntawm elasticity nrog lub zog kho tshuab. Kev txhim kho ib qho khoom feem ntau los ntawm tus nqi ntawm lwm qhov, ua rau nws nyuaj rau cov tuam txhab tsim khoom los tsim cov qauv TPE uas tswj hwm qhov sib npaug ntawm cov yam ntxwv xav tau. Tsis tas li ntawd, TPEs muaj kev cuam tshuam rau qhov chaw puas tsuaj xws li khawb thiab marring, uas tuaj yeem cuam tshuam tsis zoo rau ob qho tib si tsos thiab kev ua haujlwm ntawm cov khoom ua los ntawm cov ntaub ntawv no.